Water treatment plants play a critical role in public health and environmental stewardship. Yet, many of these facilities still operate with legacy automation systems installed decades ago. While these systems may have proven reliable over the years, they often fall short when it comes to energy efficiency. Rising energy costs, growing environmental regulations, and the push for more sustainable operations make modernizing these systems a practical and strategic move. Fortunately, plant managers can take actionable steps to improve energy performance without replacing their entire infrastructure.

Understanding the Energy Drain of Legacy Systems

Older automation systems were not built with today’s energy standards or conservation goals in mind. Pumps and motors may be oversized or run at constant speeds regardless of actual demand. Valves, sensors, and control logic may lack the granularity to make real-time adjustments, leading to waste. In some cases, processes that could be optimized are left untouched because the existing system lacks the data collection and analytics capabilities of modern alternatives.

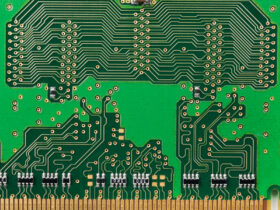

Another concern is compatibility. Legacy programmable logic controllers (PLCs) and human-machine interfaces (HMIs) may not communicate efficiently with newer devices, forcing workarounds that hinder optimization. These mismatches not only cost energy but can increase maintenance time and downtime—two areas where energy use can quietly add up.

Incremental Upgrades That Make a Big Impact

Replacing an entire control system can be cost-prohibitive and disruptive. Instead, plant managers can pursue incremental upgrades that generate returns both in savings and performance. Here are some of the most effective strategies.

1. Upgrade Variable Frequency Drives (VFDs)

One of the simplest yet most effective energy efficiency upgrades is installing or replacing outdated VFDs. These devices adjust motor speeds to match process demands, rather than running motors at full power constantly. In applications like influent pumping, blower control, and chemical dosing, the energy savings can be substantial—often exceeding 30%. Modern VFDs also come with improved diagnostics and networking capabilities that can integrate with existing automation systems.

2. Replace Obsolete Sensors with Smart Devices

Many older plants still rely on analog sensors for flow, level, pressure, and temperature monitoring. These sensors may drift over time, leading to inefficient process control. Upgrading to smart sensors with built-in diagnostics and digital communication protocols allows for more accurate readings and faster response times. These devices also simplify preventive maintenance and reduce energy use tied to inaccurate control setpoints.

3. Optimize Pump Control Sequences

Pumps are among the largest energy consumers in any water treatment plant. Rather than operating based on static schedules or manual oversight, pumps can be sequenced and adjusted dynamically based on flow demand, tank levels, or time-of-day considerations. Advanced control logic—even when layered onto a legacy system—can reduce runtime and eliminate redundant cycles.

4. Improve SCADA Visualization and Reporting

Supervisory control and data acquisition (SCADA) systems are vital for monitoring and managing plant operations. Upgrading visualization interfaces and enabling better data logging can help operators identify patterns in energy use. By analyzing these trends, managers can make informed decisions about load shifting, process timing, or prioritizing which systems to upgrade next.

5. Introduce Energy Monitoring Subsystems

Sometimes, the biggest challenge is not knowing where energy is going. Installing submetering systems across high-consumption equipment—such as aeration blowers, UV disinfection units, or chemical feed systems—gives a clearer picture of usage. This can guide future upgrades and help justify capital expenses by quantifying savings potential.

Working Within Existing Automation Frameworks

Many of these improvements can be integrated into current automation systems with limited disruption. Industrial automation vendors often provide retrofit kits or communication gateways that allow new components to “speak” to older PLCs or control networks. For example, Ethernet/IP or Modbus interfaces can bridge legacy systems with modern devices.

System integrators can also help by designing custom logic or interface layers that let newer technologies operate alongside older codebases. This staged approach makes it possible to prioritize high-impact areas first, reducing capital expenditure while still seeing meaningful returns.

Consider the ROI Beyond Energy Savings

While reducing kilowatt-hours is a clear benefit, energy efficiency upgrades often deliver value in other areas. Maintenance costs tend to go down when newer components replace worn-out or unreliable parts. Operator workload is reduced with better data and automation. Even regulatory compliance can become easier, especially when energy-intensive systems like chemical dosing or disinfection are brought under tighter control.

Additionally, utilities and municipalities often offer incentives or rebates for energy-saving projects. These can help offset upfront costs, accelerating payback periods and making upgrade projects easier to justify to stakeholders or budget committees.

Making a Plan for Modernization

For water plant managers, the first step is conducting an audit of energy use and system performance. From there, a roadmap can be developed that prioritizes upgrades based on cost-effectiveness, ease of implementation, and operational impact. Working with an experienced engineering partner or automation specialist can also help uncover hidden opportunities, especially in systems that have been in place for decades.

Rather than seeing legacy automation as a burden, consider it the foundation for a more efficient future. With thoughtful planning and incremental investment, energy performance can be improved significantly—while extending the life and usefulness of your existing control systems.

Leave a Reply