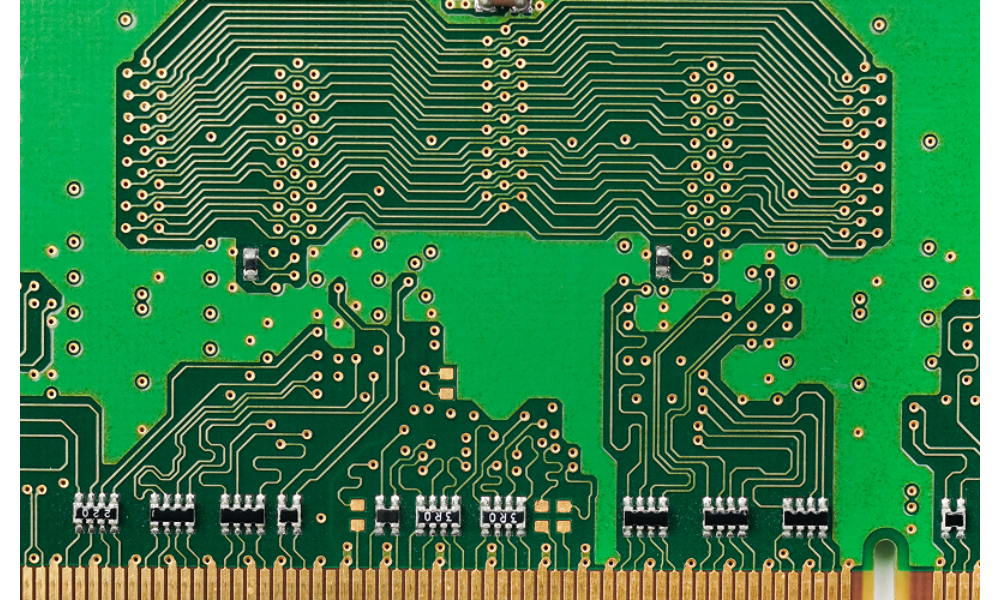

Electronics businesses rely on precision, speed, and consistency to stay competitive. As products become smaller and more complex, printed circuit boards play an even more critical role in performance and reliability. PCB Fabrication in Singapore supports these demands by combining advanced manufacturing capabilities with strict quality standards. For companies developing consumer electronics, industrial systems, or specialised devices, knowing what PCB is helps ensure better design outcomes and smoother production cycles.

What Is the PCB Fabrication Process?

PCB fabrication involves several controlled steps that turn design files into functional circuit boards. Manufacturers begin with material selection, layer stack-up planning, and imaging before moving into etching, drilling, and plating. Each step requires precision, as even small errors can affect signal integrity or component alignment. PCB Fabrication in Singapore follows international manufacturing and testing standards, which helps electronics businesses reduce defects and improve yield rates.

Local manufacturers often support a wide range of board types, including single-sided, double-sided, and multilayer PCBs. This flexibility helps businesses scale from prototypes to mass production without changing suppliers. Companies that align PCB fabrication with downstream assembly also benefit from better coordination, reduced lead times, and clearer accountability across the production workflow.

Why Singapore Is Central for PCB Fabrication

Singapore’s strong electronics ecosystem makes it a strategic location for PCB manufacturing. The country invests heavily in advanced manufacturing, automation, and workforce training, which directly benefits electronics companies. PCB Fabrication in Singapore also benefits from stable infrastructure, efficient logistics, and access to regional supply chains. These factors help businesses manage tight delivery schedules while maintaining consistent quality.

Many manufacturers integrate PCB fabrication with electronic manufacturing services, offering a complete production solution under one roof. This approach simplifies vendor management and reduces risks linked to outsourcing multiple stages to different providers. For businesses developing complex electronics, working with integrated partners improves communication and speeds up problem resolution during production.

Key Considerations When Choosing a PCB Fabrication Partner

Selecting the right fabrication partner requires more than comparing prices. Electronics businesses should assess technical capabilities, material expertise, and quality control systems. A reliable partner provides clear documentation, traceability, and testing protocols such as electrical testing and inspection. These factors help ensure boards perform as intended in real-world conditions.

Companies should also consider whether the manufacturer offers electronic manufacturing services in Singapore beyond PCB fabrication. Value-added services such as surface-mount assembly, box build, and functional testing create efficiency. Providers like MPN Tech, for example, support businesses by aligning fabrication with assembly requirements, which reduces rework and improves overall product reliability.

How Integrated Manufacturing Supports Business Growth

Integrated manufacturing helps electronics businesses move faster from concept to market. When PCB fabrication and assembly teams collaborate closely, they identify design issues early and recommend improvements that enhance manufacturability. This proactive approach reduces costly design revisions and minimises production delays.

For growing businesses, scalability is as crucial as quality. Electronic manufacturing services in Singapore often support flexible production volumes, allowing companies to ramp up output as demand increases. This adaptability proves valuable for startups and established firms, especially in industries where product lifecycles are quick and innovation is constant.

Common Challenges and How to Avoid Them

Electronics businesses often face challenges such as inconsistent quality, delayed deliveries, or communication gaps with overseas suppliers. Choosing PCB Fabrication in Singapore helps mitigate these risks through proximity, transparency, and regulatory compliance. Local manufacturing also allows easier audits, faster feedback loops, and stronger working relationships.

To avoid issues, businesses should engage fabrication partners early in the design phase. Clear specifications, design-for-manufacturing reviews, and realistic timelines all contribute to better production. A collaborative approach ensures that technical expectations align with manufacturing realities from the start.

Conclusion

PCB Fabrication in Singapore offers electronics businesses reliability, precision, and strategic advantages. With access to integrated electronic manufacturing services, companies can streamline production while maintaining high-quality standards. Careful partner selection and early collaboration remain key to long-term success in a competitive electronics market.

Contact MPN Tech to support your PCB fabrication and manufacturing needs.

Leave a Reply